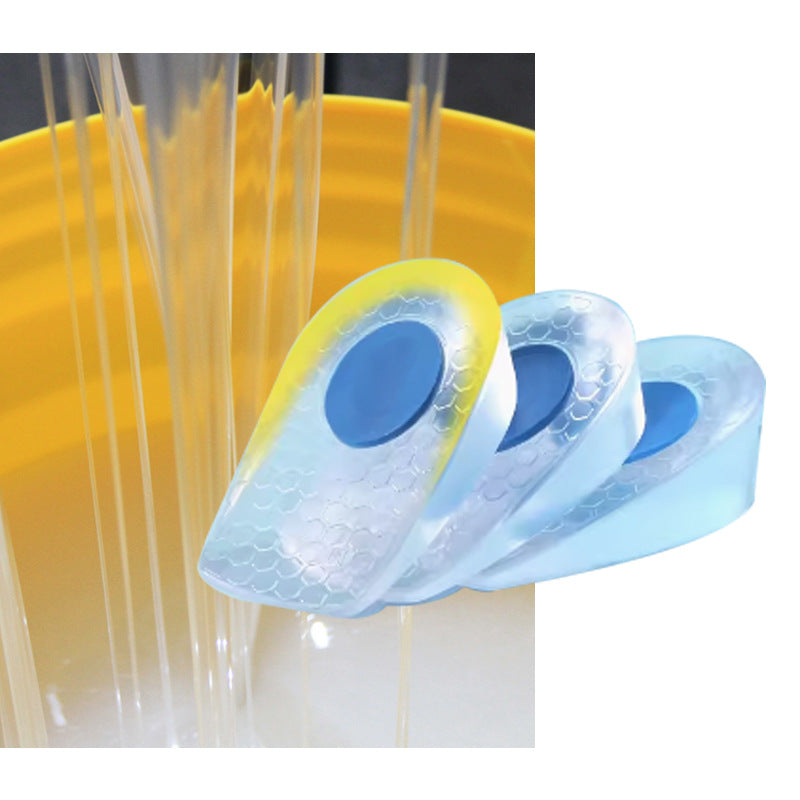

Shoe Insole Liquid Silicone Rubber – Custom OEM/ODM, Height Increase

Shoe Insole Liquid Silicone Rubber – Custom OEM/ODM, Height Increase

Description:

-

Factory Direct Supply – professional silicone manufacturer with stable quality.

-

OEM/ODM Customization – private label, formula adjustment, and packaging support.

-

Excellent Cushioning & Resilience – provides superior comfort and shock absorption.

-

Height Increase Application – ideal for producing lift/height boost insoles.

-

Safe & Skin-Friendly – non-toxic, odorless, suitable for daily wear.

-

Durable & Stable – resistant to deformation, aging, and yellowing.

-

Our liquid silicone rubber for insoles is specially designed for comfort and durability. With low shrinkage, high elasticity, and excellent tear resistance, this material ensures stable performance even after long-term use. It is widely applied in height-increasing insoles, sports insoles, orthopedic insoles, and custom shoe pads.

The material can be customized to achieve different levels of softness, resilience, and transparency. OEM/ODM services are available, allowing you to create branded products with tailored specifications.

Applications

-

Height increase insoles

-

Sports insoles (running, basketball, etc.)

-

Orthopedic / medical insoles

-

Daily comfort insoles

-

Custom shoe pads

Use-Method :

Use-Method :-

Mix Part A and Part B at a ratio of 10:1 or 1:1 by weight, depending on the product specification. Stir thoroughly and use the mixture immediately, as it must be consumed within a short working time.

-

After mixing, place the rubber material into a vacuum chamber for 3–5 minutes to remove trapped air. The mold can be used once the defoaming process is complete.

-

The curing speed of this product is highly influenced by temperature and humidity. Higher temperature and greater humidity will accelerate the curing process. Users should select the curing agent according to weather conditions and adjust the mixing ratio to achieve the desired curing rate.

-

Share